- Generator Transformers are used as step up transformer at generator end application

- Station Transformers are used to supply auxiliary load to power plant

- Unit Auxiliary Transformer are used to supply power to auxiliary equipment

- Multi winding Transformers are used in rectifier duty application

- System Transformers are used as intermediate to step down the voltage

s o l u t i o n s

Distribution Transformer

Distribution Transformers Units manufactures a wide range of Power and Distribution Transformers as well as Reactors ranging from 160kVA to 1500 MVA, 12kV ~1200kV Class, conforming to IEC, ANSI, IS, BS and other International Standards. CGPISL manufactures wide variety of Transformers like Generator Transformers, Distribution Transformers, Solar Transformers, Green Transformers, Unit Auxiliary Transformers, Shunt Reactors, Furnace Transformers, Locomotive and Track side Transformers. CGPISL is a preferred supplier for a wide range of Transformers and Reactors for many critical applications. CGPISL is the first Indian manufacturer to develop and supply coupling transformers for dynamic reactive power compensation (DRPC) applications like static synchronous compensator (STATCOM), Static VAR Compensator (SVC) etc & also the first manufacturer of 132KV Green Transformers in INDIA. CGPISL has two Plants to manufacture Transformers one located at Bhopal for Power Transformers and other located at Gwalior for Distribution Transformers, Madhya Pradesh, India. Manufacturing Units are accredited with certifications like ISO 9001, ISO 14001, ISO 18001, Integrated Management OSHAS 18001 and DSIR approved.

Low Power Transformer Up To 50 MVA, 132 Class

4MVA to 50 MVA, voltage: up to 132 kV Class. Low power transformers are power transformers that are used to change high voltage i.e. 132 Kv/66 Kv to medium voltage i.e. 33 kV/11 kV.

CG has used its in house R&D and engineering capabilities to manufacture low power transformers. The product development team has taken proven technology used in distribution transformers and applied it to LPT. Design features of clamping structures, LV and HV windings, and bushings, as well as cooling techniques have been adapted, enabling CGPISL to manufacture the LPT in a cost-effective way. Units delivering up to 50 MVA have already passed stringent performance tests and are in active service in a variety of applications.

A Oil and Gas, Infra - Projects, Mines Metal Minerals, Railways, FMCG, Power Generations, Smarts Cities, SEBs, etc.

Solar Transformer

Up To 12.5 MVA; Voltage Up To 33kV. CG developed Inverters duty transformers for solar applications, which operate at the fundamental frequency of an alternating system. These are designed for one or more output windings connected to the inverters load. Owning to multiple outputs, multiple inverters paralleled to the PV arrays are directly connected to these transformers and reduces the project cost without compromising any of the transformer functions.

We offer Inverters duty transformers having three-windings and five-windings construction specially designed for grid connected photovoltaic systems. Extra care is taken in design and manufacturing of inverter duty transformers to address the harmonics that are usually to appear in the transformer windings. These transformers are designed according to any specific customer requirements regarding voltage, power, low losses, sound level, operating conditions and more. Special attention is given to people, environmental impact and safety issues.

The transformer`s primary voltage is at the low voltage side and the secondary is at the medium voltage side. The input voltages usually take values 380 V or 400 V and the medium voltage varies according to the feeding network voltage (i.e.11, 33kV).

Five Winding Transformer

Total approx. 2000 MVA installed & running transformers in Solar power generation plants PAN INDIA.

- Proven technology of CG Global design having superior short circuit withstand Capability.

- Manufacturing technology with automatic SCADA controlled CNC machines for maintaining process parameters during windings and achieving high quality electric and mechanical connections.

- All the ratings are type tested as per IS: 2026.

- CG is partnering with global leaders for exploring potential of solar energy & introducing advance technology.

These Inverters duty transformers are the ideal solution for photovoltaic systems. The technology used along with the appropriate sizing of the core, the framework and the high quality materials results in the most suitable product in terms of quality, reliability, efficiency and cost effectiveness. Three & five winding transformer features include:

- Galvanic isolation between the solar inverter and the feeding network

- Voltage step-up from the inverter output to the MV feeding network

- Wound magnetic core for

- • standard or low losses

- • minimum sound levels and low inrush current

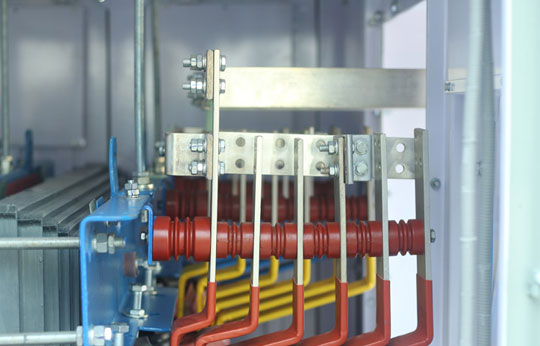

Dry Type Cast Resin Transformers

100 kVA to 10 MVA; Voltage 0.415 kV to 33 kV. CG cast resin transformers: When safety and performance are paramount CG Cast resin transformers are ideally suited for environments that demand the highest level of fire safety.

Application in:

- Office & Apartment buildings, to hospitals, underground

- Transport systems, and industrial and off-shore installations Certified safe

Suitable for power ratings from 100 kVA up to 10MVA with operating voltages up to 36 kV, the full product range meets IS 11171 and IEC 60076-11 regulations. These safety certifications guarantee that the transformers:

- Self-extinguish and emit a minimum of fumes in the event of fi re (F1);

- Reliable under conditions of high thermal shock (C2);

- Perform well in damp, dusty, salty and polluted environments (E2).

- Permium Quality Casting

- Non- Hygroscopic

- Non-Inflammable

- High short circuit strength

- High impluse strength

- Low losses

- Long life cycle

- Low Maintenance

- Low cost installation

- Space saving

- Certified safe

- State-of-the-art construction for optimum performance

- Safety features of low voltage windings

- Safety features of high voltage windings

- Optimal thermal protection

- Environment friendly

- Easy installation and connection

- Reliable

Bio Transformers up to 132 KV Class

250 kVA to 50 MVA; Voltage 3.3 kV to 132 kV. Safer and eco friendly. One of the key benefits offered by the green power transformers is the prevention of pollution through the use of ester oil instead of mineral oil. Mineral oil is used in conventional transformer design which comes from natural resources after processing of the mother earth raw materials taken from mine.

- Updated electrical design due to permittivity changes.

- Tailored cooling design due to viscosity changes.

- Experimentally validated in house design software.

- Adapted procedures for impregnation & oil filling process.

- Up gradation of manufacturing technology.

- Cost effective and reliable transformers.

- In ecologically sensitive locations.

- Specific regulations apply.

- Near rivers and lakes.

- Near drinking and groundwater reserves.

- Near crowded place.

- Industrial Transformers used in Industries to cater lighting load & load of 3 ph motors.

- Residential Transformers for distribution of power to house hold.

Metro Traction Transformers

Up To 30.24 MVA; Voltage Up To 132 kV. Traction transformers are critical components in the traction chain, affecting both train performance and operator services. ... They can be mounted either in the machine room of the train, on the roof or under the floor, providing maximum flexibility and reliability in single and multiphase systems.

- Traction transformers are critical components in the traction chain, affecting both train performance and operator services.

- CG supplies traction transformers for all applications: locomotives, tram-trains and AC metros offering different designs in terms of size, weight and power ratings.

- They can be mounted either in the machine room of the train, on the roof or under the floor, providing maximum flexibility and reliability in single and multiphase systems.

- Traction Transformers are used in Railways to give power to DC/AC motors in engine.

- Track side Transformers are used to step down the voltage to the level of catenary voltage i.e. 25 kV.