- Better short circuit strength

- Compact design

- Durability

- Optimum losses

- Lower footprint

- Low temperature rise

s o l u t i o n s

Power Transformer

Generator Transformers

Generator Step-up Transformer units are used to increase the voltage of a generator and connect the supply to a bus bar. Generator Transformers are also used to limit the fault level of the generator in case of a fault. Transformers used for these applications are called Generator Step-up Units. These Transformers are designed to operate at near full load.

Generator step-up transformers are manufactured by CG in accordance to the latest applicable national and international standards. Our transformers meet the needs of utility, industrial and commercial customers. Typical generator step-up transformers have cover-mounted primary and secondary bushings. However other configurations can be provided. Every time a fault occurs in the grid, these transformers are subjected to stress. As these transformers are connected to the grid, they are subjected to constant voltage fluctuations. Voltage fluctuations cause stress to the transformer windings. These windings have to be specially designed to withstand these stresses. Localized heating is another issue which is a result of over excitation by the generator during voltage fluctuations. Localized heating can damage the metallic accessories of the transformer. Generator step-up transformers manufactured by CG India have effective low temperature rise.

Furnace Transformers

CG offers various types of furnace transformers like arc furnace and laddle furnace transformers. Mainly the application of electrical air furnace is limited only for melting and refining carried out in next stage. The range of voltages are small for melting operations since furnaces are designed with specific apparent power density in the order of 600-800 kVA / ton. The laddle furnace transformers are used in refining molten steel. The range of voltage required is smaller and lower than those of electrical arc furnace transformers. Normal range arc has low specific apparent average power density in the order of 200-400 kVA / ton. A transformer supplying power to a furnace has to handle extremely high value currents in the order of kAmps. (10 to 60 or higher depending upon furnace ratings).

The furnace transformer thus has special features to handle such high currents as compared to conventional transformers. The electric arc furnace has 3 electrodes connected to the secondary terminals of the furnace transformers. The secondary terminals of the transformers are subject to frequent short circuits during the melting process through the charge and arc. Hence the furnace transformer needs to be specially designed to withstand the frequent short circuits.

- Compliant with IEC, ANSI, BIS, ISO and other international standards

- Customized to customer’s specifications

- Capable to withstand extreme environmental conditions

- Capable to withstand seismic, wind and ice loads

- Capable to withstand transport shocks

- Low noise and vibration levels

- Low weight and less carbon footprint

- Easy assembly with fewer loose parts

- Arrangements for worker safety at substations

- Compact size requires lower expenditure on civil structures

- Easily transportable to remote sites with narrower roads

- Transportability through road, rail, sea and air

- Require low maintenance

Locomotive and Trackside Power Transformers

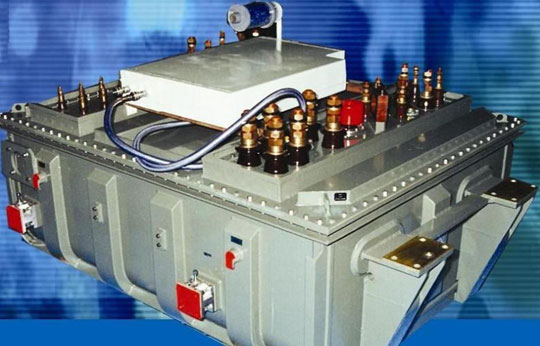

The Locotransformer is used for stepping down the voltage level required for motors used in the railway engines. This transformer has low dimension and weight limits. Height of the unit is reduced by mounting the active part horizontally. We have different range of uniquely designed products like 3900 kVA Foil Wound, 5400 kVA Foil Wound, 6500 kVA for 3-phase Loco, 7500 kVA for 3-phase Loco with advanced design technology to perform seismic and short-circuit conditions, which is developed over the past experiences accompanied with high-end technology for the manufacturing and quality tools for cost-effectiveness for long life with low maintenance.

They are designed with H class conductor insulation and filled with silicone oil. To get a compact but reliable design OFAF or ODAF cooling is applied. Height of the unit is reduced by mounting the active part horizonally.

The Trackside Power Transformers are used for stepping down the voltage levels for the railway network. They are used to provide single phase supplies for train overhead systems. The duty of traction supplies transformers is a particularly difficult one, as overloading up to twice full-load current can appear. Furthermore, trackside transformers need to withstand system short-circuits which may be as high as 250 per year of varying magnitude up to full fault current. Height of the unit is reduced by mounting the active part horizontally. We have a wide range of uniquely designed products with advanced design technology to perform seismic and short-circuit conditions.

These products are developed over the past experiences and high end technology for the manufacturing and quality tools. Thus these are cost-efficient with long operating life, providing a platform for customer’s delight.

- Unique designs

- Optimum losses

- Long life

- Sustain durability

- Low maintainance

- Short circuit tested Transformers